O&K boiler company has a team consisting of technically competent boiler maintenance engineers and professional technicians with years of experience, who can carry out professional testing, maintenance, fixing up and cleaning of marine boilers, heat exchangers, pressure vessels and other equipment. Our team also has rich experience in on-site operation, especially in welding, which is outstanding and can reach 100% of the Ray and UT flaw detection. They also have been accredited WPS certification by several classification societies such as LR,NK, DNVGL,ABS,CCS etc. O&K Marine company has set up managing offices and processing workshops in several places including Qingdao, Zhoushan, etc. It fits large processing equipment such as drilling machine, fin tube machine, pin tube machine, pipe bending machine, shrink tube machine and coil machine, which can provide customers not only with boiler inspection, maintenance, repair, cleaning up, but can also provide one-stop service to meet customer's all-round requirements on the processing of spare parts such as pipes and tube sheets.

Our company has pin tube welding machine, fin tube welding machine, pipe spiral processing machine, pipe bending machine and other boiler tube machinery equipment, also can produce boiler tube and tube group spare parts by Class LR, NK, DNV, ABS, CCS and other classification society approved . We can satisfied necessary of customers.

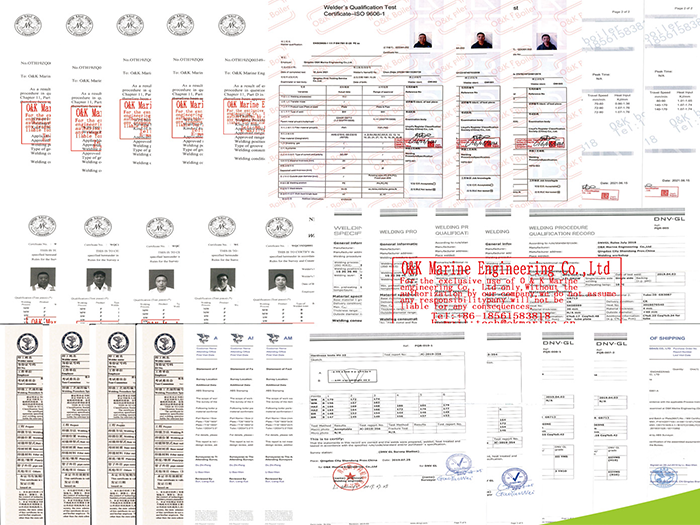

We have aviation repair qualification and welding certificate approved by LR, NK, DNVGL, ABS, CCS and other classification societies

We have a large number of skilled and qualified technicians, and they have more than 10 years of rich experience in site construction and have the classification society recognized welding level. We have provided on-site repair services to MSC, PB, MAERSK, CENTURY BULK, BERNHARD, DASIN and other customers.

Our company has developed a series of chemical cleaning agent for boilers, such as crude oil cleaning agent and scale remover.Characteristics of the agent as following :2.Good water solubility; 3.High oil removal efficiency, fast speed, oil removal rate can reach more than 99%. 4.The chemical cleaning agent is non-corrosive to metals, glass, plastics and wood. 5.The chemical cleaning agent is mainly aimed at the oil which is hard to easy to clean, such as crude oil, heat conducting oil, asphalt drying, etc.

For incinerator repair, the working temperature of refractory material can reach 1200℃, and the maximum temperature can reach 1800℃. The strength can reach 600#, 700#. We use one-time complete casting molding process on site. Products not only beautiful appearance, but also good ventilation, combustion, durable. The normal service life is 5 years.